أحدث فولاذ المنغنيز ثورةً في علم المعادن والصناعات الثقيلة بفضل قوته ومتانته الاستثنائية. اكتشفه السير روبرت هادفيلد عام ١٨٨٢، ويجمع هذا السبائك بين الحديد والكربون والمنغنيز لإنتاج مادة فريدة من نوعها. وقد جعلته قدرته الفريدة على التصلب تحت تأثير الصدمات نقطة تحول في عالم الأدوات والآلات وتطبيقات البناء.

تنبع الخصائص المميزة لفولاذ المنغنيز من دوره المحوري في صناعة الفولاذ. فهو لا يزيل الشوائب مثل الكبريت والأكسجين فحسب، بل يعزز أيضًا صلابته ومقاومته للتآكل بشكل ملحوظ. ومع مرور الوقت، ساهمت التطورات، مثل المعالجات الحرارية وتقنيات التصنيع المتطورة، في توسيع إمكانات...صفائح الفولاذ المنغنيز, صفيحة فولاذية منجنيزية، وبطانات من الفولاذ المنغنيز.

اليوم، الفولاذ المنغنيز وصفائح فولاذ المنغنيزوتستمر هذه المواد في العمل كمواد أساسية في الصناعات التي تتطلب مقاومة عالية للتأثيرات، بما في ذلك التعدين والسكك الحديدية.

النقاط الرئيسية

- فولاذ المنغنيزتم اختراعه من قبل السير روبرت هادفيلد في عام 1882.

- إنه قوي جدًا ويصبح أكثر صلابة عند الضرب، مما يجعله رائعًا للمهام الصعبة.

- أدت عملية بسمر إلى تحسين فولاذ المنغنيز من خلال إزالة الشوائب.

- كما أن هذه العملية جعلت الفولاذ أقوى وأطول عمراً.

- يستخدم الفولاذ المنغنيز في التعدين والسكك الحديدية والبناء لأنهيقاوم التآكل.

- تساعد متانتها على خفض تكاليف الإصلاح وتجعل المعدات تدوم لفترة أطول.

- طرق جديدة لخلط السبائك وجعل الفولاذ يحسن أدائه اليوم.

- يعد إعادة تدوير الفولاذ المنغنيز أمرًا مهمًا للحفاظ على الموارد ومساعدة الكوكب.

أصول فولاذ المنغنيز

اكتشاف السير روبرت هادفيلد

بدأت قصة فولاذ المنغنيز مع السير روبرت هادفيلد، عالم المعادن البريطاني الذي حقق اكتشافًا رائدًا عام ١٨٨٢. فقد وجد أن إضافة المنغنيز إلى الفولاذ تُنتج سبيكة ذات خصائص استثنائية. وعلى عكس الفولاذ التقليدي، كانت هذه المادة الجديدة صلبة ومتينة، مما يجعلها مثالية للتطبيقات عالية التأثير.

لم يخلو عمل هادفيلد من التحديات. ففي وقت مبكر، لاحظ أن فولاذ المنغنيز يقاوم التشغيل الآلي ولا يُعالج بالتلدين، مما صعّب العمل به. ومع ذلك، لم تثنه هذه العقبات، بل أبرزت الطبيعة الفريدة لهذه السبيكة وقدرتها على إحداث ثورة في الصناعات.

- تتميز الفولاذ المنغنيز بصلابة وقوة تصلب ذاتية مما يجعله متميزًا عن المواد الأخرى.

- وأكدت نتائج هادفيلد أن المنجنيز هو العنصر الأساسي المسؤول عن هذه الخصائص الرائعة.

التجارب المبكرة وتطوير السبائك

أثار اكتشاف هادفيلد موجةً من التجارب لتحسين هذه السبيكة وفهم سلوكها. ركز الباحثون على كيفية تفاعل المنغنيز مع عناصر أخرى كالكربون والحديد. وأرست هذه الدراسات المبكرة أسس فولاذ المنغنيز الذي نعرفه اليوم.

كانت الممارسة القديمة للتعامل مع سبائك فولاذ المنغنيز، منذ عام ١٨٨٧ فصاعدًا، تتمثل في تسخين السبائك إلى درجات حرارة أعلى بكثير من درجات الحرارة التي يشير إليها السيد بوتر. قبل عام ١٩٠٠ بوقت طويل، صُنعت واستُخدمت آلاف الأطنان من هذه المنتجات المطروقة والمدلفنة. في الورقة التي قدمها الكاتب إلى هذا المعهد عام ١٨٩٣، بعنوان "سبائك الحديد، مع إشارة خاصة إلى فولاذ المنغنيز"، تُعرض تفاصيل وصور كاملة لفولاذ المنغنيز المطروق في محاور السكك الحديدية والمدلفن في إطاراتها.

أثناء تجارب الباحثين، اكتشفوا تفاصيل مذهلة حول انتقالات طور السبائك وبنيتها الدقيقة. على سبيل المثال، تناولت إحدى الدراسات سبيكة متوسطة المنغنيز مصممة للتشكيل. كشفت النتائج كيف أثرت معدلات التسخين وأوقات النقع على خصائص المادة.

| النتائج | وصف |

|---|---|

| انتقالات الطور | ركزت الدراسة على التحولات الطورية في سبيكة متوسطة المنغنيز، وتحديداً 0.19C-5.4Mn-0.87Si-1Al، المصممة للتشكيل. |

| التناقضات | وقد سلط البحث الضوء على التناقضات بين المحاكاة الديناميكية الحرارية والنتائج التجريبية، مؤكداً على الحاجة إلى دراسة متأنية لمعدلات التسخين، وأوقات النقع، والبنية الدقيقة الأولية. |

ساعدت هذه التجارب في تحسين تركيب الفولاذ المنغنيز، مما جعله أكثر موثوقية وتنوعًا للاستخدام الصناعي.

براءات الاختراع والطلبات الأولية

بلغ عمل هادفيلد ذروته في تسجيل براءة اختراعفولاذ المنغنيزفي عام ١٨٨٣، كانت هذه بداية رحلته نحو التطبيقات العملية. قدرة السبائك على التصلب تحت تأثير الصدمات جعلتها نقطة تحول في صناعات مثل التعدين والسكك الحديدية.

كان من أقدم استخدامات فولاذ المنغنيز صناعة قضبان السكك الحديدية ومحاورها. جعلته متانته ومقاومته للتآكل مثاليًا لتحمل الأحمال الثقيلة والاحتكاك المستمر للقطارات. مع مرور الوقت، بدأ المصنعون باستخدامه في مجالات أخرى.أدوات عالية التأثيروالآلات، مما عزز مكانتها في التاريخ الصناعي.

لم يقتصر ابتكار هادفيلد على ابتكار مادة جديدة فحسب، بل فتح آفاقًا جديدة في علم المعادن. أصبح فولاذ المنغنيز رمزًا للتقدم، مُثبتًا أن العلم والصناعة قادران على العمل معًا لحل مشاكل العالم الحقيقي.

التطورات في تكنولوجيا الفولاذ المنغنيز

عملية بسمر ودورها

العملية بسمرلعب المنغنيز دورًا محوريًا في التطوير المبكر لفولاذ المنغنيز. وقد أتاحت هذه الطريقة المبتكرة في صناعة الفولاذ، والتي طُرحت في منتصف القرن التاسع عشر، للمصنعين إنتاج الفولاذ بكفاءة أكبر من خلال إزالة شوائب مثل الكربون والسيليكون. وعندما أجرى السير روبرت هادفيلد تجارب على المنغنيز في الفولاذ، أصبحت عملية بسمر أداةً أساسيةً لتكرير السبائك.

من خلال دمج المنغنيز في العملية، تمكن صانعو الصلب من إنتاج مادة ذات قوة ومتانة معززتين. كما ساعدت هذه العملية على التخلص من الكبريت والأكسجين، اللذين كانا يُضعفان الفولاذ التقليدي في كثير من الأحيان. مهّد هذا الإنجاز الطريق لاعتماد فولاذ المنغنيز على نطاق واسع في التطبيقات الصناعية.

شرح خصائص التصلب بالعمل

من أبرز مميزات فولاذ المنغنيز قدرته على التصلب تحت تأثير الصدمات. هذه الخاصية، المعروفة باسم التصلب الناتج عن العمل، تحدث عندما تتعرض المادة للتشوه. فمع تعرض السطح للإجهاد، يصبح أكثر صلابة ومقاومة للتآكل.

أظهرت الدراسات أن هذا التأثير يتأثر بعوامل مثل درجة الحرارة والبنية الدقيقة للمادة. على سبيل المثال، كشفت الأبحاث التي أُجريت على الفولاذ منخفض الكربون وعالي المنغنيز أن التوأمة الميكانيكية والتحولات المارتنستية تُحسّنان القوة والمرونة بشكل ملحوظ.

| وجه | وصف |

|---|---|

| مادة | الفولاذ منخفض الكربون وعالي المنغنيز |

| درجات حرارة التشوه | -40 درجة مئوية، 20 درجة مئوية، 200 درجة مئوية |

| الملاحظات | تعمل التحولات الناجمة عن الإجهاد والتوائم الميكانيكية على تعزيز الخصائص. |

| النتائج | تؤثر درجة الحرارة على سلوك التصلب الانفعالي وتطور البنية الدقيقة. |

تجعل هذه الخاصية الفريدة الفولاذ المنغنيز مثاليًا للبيئات ذات التأثير العالي مثل التعدين والبناء.

التحسينات في تركيب السبائك

على مر السنين، قام الباحثونتحسين التكوينمن فولاذ المنغنيز لتحسين أدائه. وقد أدت إضافة عناصر مثل الألومنيوم والسيليكون إلى تطورات ملحوظة. على سبيل المثال، تُعزز زيادة محتوى الألومنيوم قوة الخضوع ومقاومة التآكل، مع أنها قد تُقلل من اللدونة.

| تكوين السبائك | درجة حرارة المعالجة الحرارية | مقاومة التآكل | النتائج |

|---|---|---|---|

| السيليكون | 700 درجة مئوية | مُحسّن | أفضل مقاومة للتآكل تحت الأحمال ذات التأثير العالي. |

| فولاذ المنغنيز المتوسط | متنوع | تم تحليلها | إطار عمل يربط بين التركيب والخصائص. |

وقد أدت هذه التحسينات إلى جعل الفولاذ المنغنيز أكثر تنوعًا، مما يضمن بقائه حجر الأساس في الصناعة الحديثة.

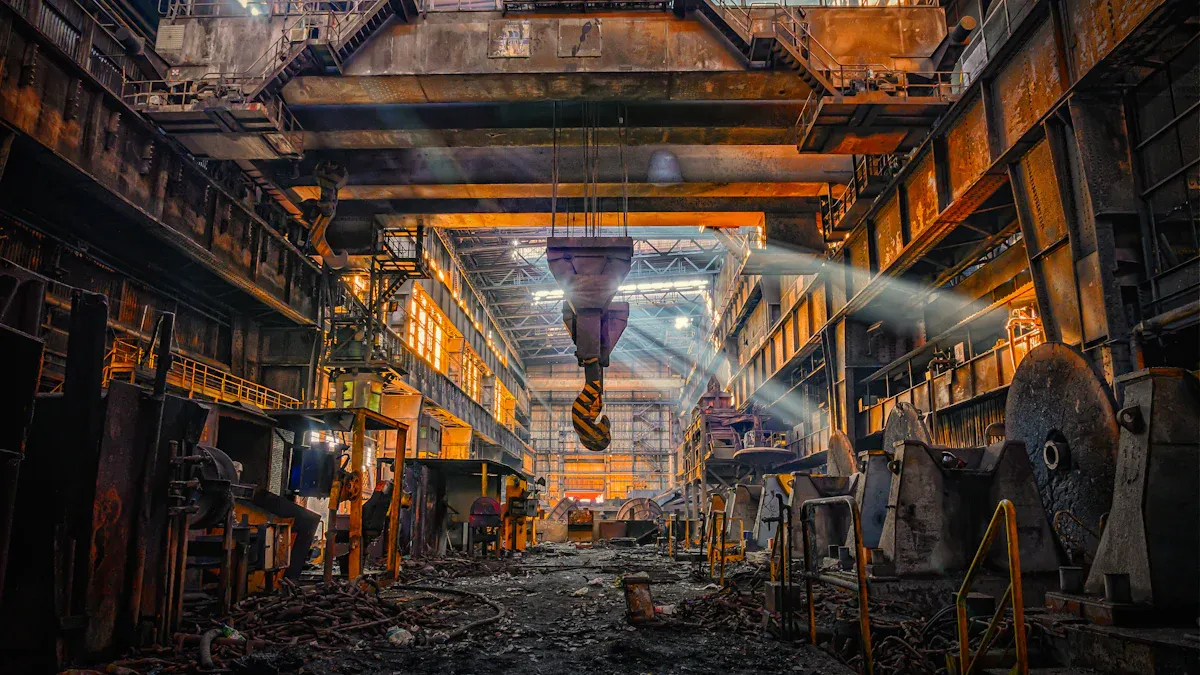

التطبيقات الصناعية للصلب المنغنيز

معدات التعدين والمحاجر

يلعب فولاذ المنغنيز دورًا حيويًا في عمليات التعدين والمحاجر. فمقاومته العالية للتآكل وقدرته على التصلب تحت تأثير الصدمات تجعله المادة المثالية للمعدات التي تواجه ظروفًا قاسية يوميًا. غالبًا ما تتعامل الأدوات والآلات في هذه الصناعات مع مواد كاشطة وأحمال ثقيلة واحتكاك مستمر. يُلبي فولاذ المنغنيز هذا التحدي، إذ يُطيل عمر المعدات ويُقلل تكاليف الصيانة.

وفيما يلي بعض التطبيقات الشائعة:

- فكوك الكسارةهذه المكونات تسحق الصخور والخامات، وتتحمل الضغط والصدمات الشديدة. يضمن فولاذ المنغنيز ديمومتها لفترة أطول.

- شاشات جريزلي:تستخدم هذه الشاشات لفرز المواد، وتستفيد من صلابة الفولاذ المنغنيز ومقاومته للتآكل.

- المزالق الحجرية:تعمل هذه القنوات على توجيه المواد عبر الآلات، حيث يمنع الفولاذ المنغنيز التآكل الناتج عن التدفق المستمر.

- دلاء المجرفةفي التعدين، تجرف دلاء الجرافات الأحمال الثقيلة من الصخور والحطام. يُحافظ الفولاذ المنغنيزي على متانتها وموثوقيتها.

باستخدام فولاذ المنغنيز في هذه التطبيقات، توفر الصناعات الوقت والمال مع الحفاظ على الكفاءة. خصائصه الفريدة تجعله لا غنى عنه في معدات التعدين والمحاجر.

مسارات السكك الحديدية والآلات الثقيلة

تعتمد السكك الحديدية على فولاذ المنغنيز في مساراتها ومكوناتها. فصلابة هذه المادة ومقاومتها للتآكل تجعلها مثالية لتحمل الاحتكاك المستمر والأحمال الثقيلة للقطارات. وقد زاد التوسع العالمي وتحديث شبكات السكك الحديدية من الطلب عليها.

تُسلّط تقارير من سوق فولاذ المنغنيز الأوستنيتي الضوء على استخدامه الواسع في قطاع السكك الحديدية. يستخدمه المصنّعون لإنتاج مسارات ومفاتيح ومعابر متينة قادرة على تحمّل الصدمات المتكررة. تضمن قدرته على تحمّل هذه الظروف سلاسة التشغيل وتقلّل الحاجة إلى الاستبدال المتكرر.

أدى نمو صناعة السكك الحديدية أيضًا إلى زيادة الطلب على فولاذ المنغنيز في الآلات الثقيلة. تتطلب القاطرات وعربات الشحن مكونات قادرة على تحمل الضغط والصدمات العالية. يتميز فولاذ المنغنيز بأداء لا مثيل له، مما يجعله الخيار الأمثل لهذه التطبيقات.

لا تزال الاستثمارات في البنية التحتية للنقل تُحفّز الابتكار في تكنولوجيا فولاذ المنغنيز. ومع توسّع السكك الحديدية، تظلّ هذه المادة حجر الزاوية في هذه الصناعة، مما يضمن الكفاءة والموثوقية.

أدوات البناء والأدوات عالية التأثير

مواقع البناء بيئات قاسية، والأدوات المستخدمة فيها تحتاج إلى أن تكون أكثر متانة. يتألق فولاذ المنغنيز في هذا المجال، إذ يوفر متانة لا مثيل لها ومقاومة فائقة للصدمات. من معدات الهدم إلى أسنان الحفارات، تتعدد استخداماته وتتنوع.

لنأخذ الأدوات عالية التأثير على سبيل المثال. تتعرض رؤوس مطرقة الثقب وحواف القطع لضغط مستمر أثناء الاستخدام. يضمن فولاذ المنغنيز بقاءها حادة وفعّالة حتى بعد التعرض لفترات طويلة للأسطح الصلبة. وبالمثل، تستفيد آلات البناء، مثل الجرافات واللوادر، من قدرة فولاذ المنغنيز على مقاومة التآكل والتلف.

بالإضافة إلى الأدوات، يُستخدم فولاذ المنغنيز في المكونات الإنشائية. تعتمد الجسور والعوارض وغيرها من العناصر الحاملة للأحمال على قوته للحفاظ على ثباتها تحت الأحمال الثقيلة. كما أن تعدد استخداماته يجعله عنصرًا قيّمًا في مجال الإنشاءات، حيث لا يمكن المساومة على المتانة والموثوقية.

من خلال دمج فولاذ المنغنيز في أدوات البناء والأدوات عالية التأثير، يمكن للصناعات إنجاز المشاريع الصعبة بثقة. خصائصه الفريدة تجعله مادةً يثق بها البناؤون والمهندسون.

مقارنة الفولاذ المنغنيز بالمواد الأخرى

المزايا في المتانة ومقاومة الصدمات

يتميز فولاذ المنغنيز بمتانته الاستثنائية وقدرته على مقاومة الصدمات. تركيبته الفريدة، التي تشملمستويات عالية من المنغنيزبفضل تركيبته الغنية بالكربون، يتصلب سطحه مع الحفاظ على نواة صلبة. هذا المزيج يجعله مثاليًا للبيئات عالية التأثير، مثل التعدين والبناء.

بخلاف العديد من المواد الأخرى، يتمتع فولاذ المنغنيز بقدرة امتصاص طاقة كبيرة تحت الضغط. تُعرف هذه الخاصية بالتصلب بالعمل، مما يعزز مقاومته للتآكل بمرور الوقت. على سبيل المثال، في التطبيقات التي تنطوي على خدش أو تآكل شديد الإجهاد، يصبح سطح المادة أكثر صلابة مع الاستخدام. ومع ذلك، قد يختلف أداؤه باختلاف الظروف. ففي ظل الأحمال المتوسطة أو منخفضة التأثير، قد لا يتصلب فولاذ المنغنيز بنفس الفعالية، مما قد يحد من متانته في مثل هذه الحالات.

تُظهر الأبحاث أن فولاذ المنغنيز، المعروف أيضًا باسم فولاذ هادفيلد، يتفوق على المواد الأخرى في مقاومة التآكل في ظروف الصدمات الشديدة. كما تُسهم قدرته على تثبيت الطور الأوستنيتي في متانته وفعاليته من حيث التكلفة مقارنةً بالسبائك القائمة على النيكل.

التحديات والقيود

على الرغم من نقاط قوته، يواجه فولاذ المنغنيز بعض التحديات الملحوظة. ومن أبرزها انخفاض قوة الخضوع الأولية، والتي تتراوح عادةً بين 200 و300 ميجا باسكال. ورغم أن هذه المادة قابلة للتصلب تحت تأثير الصدمات، إلا أن قوة الخضوع المنخفضة هذه قد تجعلها أقل فعالية في التطبيقات ذات الأحمال المتوسطة أو الثابتة.

هناك قيد آخر يتعلق بمرونته. غالبًا ما يتم تعزيز قوة فولاذ المنغنيز من خلال المعالجةيقلل من مرونتهمما يُحدث توازنًا بين المتانة والهشاشة. إضافةً إلى ذلك، قد تتشكل بعض المراحل، مثل المرحلة السداسية المُكدسة بإحكام (HCP)، أثناء المعالجة. تزيد هذه المراحل من خطر الكسور، مما يُعقّد استخدامها في بعض الصناعات.

المواد والابتكارات المتنافسة

أدى تطوير مواد وتقنيات جديدة إلى منافسة فولاذ المنغنيز. وقد أدى التقدم في البحوث المعدنية إلى ابتكار سبائك ومركبات عالية الأداء تتحدى هيمنته.

- تقدم الابتكارات في مجال السبائك المعدنية، مثل الفولاذ المنجنيز المتوسط، خصائص ميكانيكية محسنة وتوفير التكاليف من خلال تقليل عناصر السبائك.

- تتيح تقنيات التصنيع الإضافي إنتاج مواد مخصصة ذات خصائص مثالية لتطبيقات محددة.

- إن الصناعات مثل صناعة السيارات والطيران هي التي تدفع الطلب على المواد خفيفة الوزن وعالية القوة، والتي غالبًا ما تتطلب اختبارات معدنية متقدمة لضمان السلامة والامتثال.

وفي حين يظل الفولاذ المنغنيز حجر الزاوية في الصناعات الثقيلة، فإن هذه الابتكارات تسلط الضوء على الحاجة إلى إجراء أبحاث مستمرة للحفاظ على أهميته في السوق التنافسية.

الفولاذ المنغنيز اليوم والاتجاهات المستقبلية

الاستخدامات الصناعية الحديثة

يستمر الفولاذ المنغنيز في اللعبيلعب المنغنيز دورًا حيويًا في الصناعات الحديثة. متانته ومقاومته للصدمات تجعله لا غنى عنه في قطاعات مثل البناء والنقل والتصنيع. في الواقع، تُغطي صناعة الصلب ما بين 85% و90% من الطلب على المنغنيز، مما يُبرز أهميته في إنتاج سبائك عالية القوة.

| الصناعة/التطبيق | نسبة الطلب على المنغنيز |

|---|---|

| صناعة الصلب | من 85% إلى 90% |

| البناء والآلات والنقل | الاستخدامات النهائية الرائدة |

| الاستخدامات غير المعدنية | الأسمدة النباتية، أعلاف الحيوانات، الملونات للطوب |

إلى جانب الاستخدامات التقليدية، تكتسب سبائك المنغنيز زخمًا متزايدًا في صناعة السيارات. تُسهم المواد خفيفة الوزن المصنوعة من فولاذ المنغنيز في تحسين كفاءة استهلاك الوقود وأداء السلامة. ويتماشى هذا التحول مع الطلب المتزايد على حلول توفير الطاقة في قطاع النقل.

يضمن تنوع الفولاذ المنغنيز استمرار أهميته في الصناعات التي تعطي الأولوية للقوة والمتانة والابتكار.

جهود الاستدامة وإعادة التدوير

أصبحت الاستدامة محورًا رئيسيًا في صناعة الصلب، ولا يُستثنى منها صلب المنغنيز. تلعب إعادة التدوير دورًا محوريًا في تقليل النفايات والحفاظ على الموارد. تُقيّم مقاييس مثل معدل إعادة التدوير في نهاية العمر الافتراضي (EoL-RR) ومعدل كفاءة عملية إعادة التدوير (RPER) مدى فعالية إعادة استخدام مواد الخردة.

| مؤشر | اختصار | وصف مختصر |

|---|---|---|

| إجمالي معدل إعادة تدوير الخردة | TS–RIR | يقيس نسبة إجمالي مدخلات الخردة لإعادة التدوير إلى إجمالي مدخلات المواد. |

| معدل إعادة التدوير في نهاية العمر | نهاية الحياة - RR | يقيس نسبة الخردة القديمة التي يتم إعادة تدويرها إلى إجمالي الكمية المولدة سنويًا. |

| معدل كفاءة عملية إعادة التدوير | معدل العائد على السهم | يقيس نسبة إجمالي الخردة المعاد تدويرها إلى إجمالي مدخلات الخردة لإعادة التدوير. |

إن جهود إعادة تدوير فولاذ المنغنيز لا تقتصر على الحد من الأثر البيئي فحسب، بل تعزز أيضًا الاكتفاء الذاتي في إمدادات المواد. وتتماشى هذه المبادرات مع الأهداف العالمية للتنمية المستدامة، مما يضمن قدرة الصناعات على تلبية الاحتياجات المستقبلية بمسؤولية.

التقنيات والتطبيقات الناشئة

يبدو مستقبل فولاذ المنغنيز واعدًا بفضل التقدم التكنولوجي والاحتياجات الصناعية المتغيرة. في كوريا الجنوبية، يشهد سوق فولاذ المنغنيز والبورون نموًا ملحوظًا بفضل تطبيقاته في قطاعي السيارات والبناء. وقد أدى انتشار المركبات الكهربائية إلى زيادة الطلب على المواد المبتكرة، مما مهد الطريق لاستخدامات جديدة لفولاذ المنغنيز.

- يدعم الفولاذ المنغنيز التقنيات المستدامة مثل معالجة مياه الصرف الصحي المنغنيزية بالتحليل الكهربائي.

- يلعب دورًا مهمًا في أنظمة تخزين الطاقة والتطبيقات الطبية الحيوية.

- إن عمليات الدمج والاستحواذ في قطاع الصلب هي التي تدفع عجلة الابتكار ونمو السوق.

مع استكشاف الصناعات لإمكانيات جديدة،يظل الفولاذ المنغنيز حجر الزاويةالتقدم. تضمن خصائصه المتعددة قدرته على التكيف مع الاتجاهات والتقنيات الناشئة.

ترك فولاذ المنغنيز بصمةً لا تُمحى في علم المعادن والصناعة منذ اكتشافه في القرن التاسع عشر. وقد قدّم العمل الرائد للسير روبرت هادفيلد مادةً قادرةً على التصلب تحت تأثير الصدمات، مُحدثًا ثورةً في تطبيقات التعدين والسكك الحديدية والبناء. ومع مرور الوقت، حسّنت التطورات، مثل المعالجات الحرارية وتحسين السبائك، خصائصه الميكانيكية، مما ضمن استمرار أهميته في البيئات عالية التأثير.

تتميز الفولاذات متوسطة المنغنيز، التي تتراوح تركيباتها بين 3% و10% منغنيز، ببنيات دقيقة فريدة ومتانة استثنائية. وقد دفعت أساليب الإنتاج، مثل التشوه والتقسيم (D&P)، بمقاومة الخضوع إلى مستويات مذهلة، مما يجعلها مثالية لتطبيقات التصلب بالضغط.

بالنظر إلى المستقبل، تواجه الصناعة تحدياتٍ كالمخاوف البيئية وارتفاع تكاليف التشغيل. ومع ذلك، تتوافر فرصٌ واعدة. ويُبرز الطلب المتزايد على سبائك المنغنيز في إنتاج الصلب وحلول تخزين الطاقة المتجددة أهميتها الاستراتيجية.

| فئة | تفاصيل |

|---|---|

| العوامل الرئيسية المحركة | - تزايد استخدام المركبات الكهربائية التي تعمل ببطاريات الليثيوم أيون. |

| - ارتفاع أنشطة تطوير البنية التحتية على مستوى العالم. | |

| القيود الموجودة | - المخاطر الصحية المرتبطة بالتعرض للمنجنيز. |

| الفرص الناشئة | - التقدم في تكنولوجيات التعدين والممارسات المستدامة. |

إن قدرة فولاذ المنغنيز على التكيف مع التقنيات الناشئة تضمن له مكانةً في مستقبل الصناعة. فمن أنظمة تخزين الطاقة إلى علم المعادن المتقدم، لا يزال تنوعه يُسهم في دفع عجلة الابتكار والاستدامة.

التعليمات

ما الذي يجعل الفولاذ المنغنيز مميزًا جدًا؟

الفولاذ المنغنيز فريد من نوعهلأنه يتصلب عند التعرض للصدمات. هذه الخاصية، المعروفة باسم التصلب الناتج عن العمل، تجعله أكثر صلابة كلما زاد استخدامه. وهو مثالي للأدوات والآلات عالية التأثير التي تتعرض للتآكل والتلف المستمر.

هل يمكن إعادة تدوير الفولاذ المنغنيز؟

نعم! إعادة تدوير فولاذ المنغنيز يُساعد على تقليل النفايات والحفاظ على الموارد. تُعيد الصناعات استخدام مواد الخردة لإنتاج منتجات جديدة، مما يجعله خيارًا صديقًا للبيئة للتصنيع المستدام.

أين يستخدم الفولاذ المنغنيز عادة؟

يُستخدم فولاذ المنغنيز في معدات التعدين، وخطوط السكك الحديدية، وأدوات البناء. متانته ومقاومته للصدمات تجعله مثاليًا للبيئات التي تتعرض فيها المواد لضغط شديد.

هل الفولاذ المنغنيز أفضل من المواد الأخرى؟

في حالات الصدمات الشديدة، يتفوق فولاذ المنغنيز على العديد من المواد الأخرى. فهو أكثر صلابة ويدوم لفترة أطول. ومع ذلك، فهو ليس بنفس الفعالية في الأحمال الساكنة أو التطبيقات خفيفة الوزن، حيث قد تكون السبائك الأخرى أفضل.

كيف يساعد الفولاذ المنغنيز الصناعات على توفير المال؟

مقاومتها للتآكليقلل من الحاجة إلى الاستبدالات المتكررةتنفق الصناعات التي تستخدم الفولاذ المنغنيز مبالغ أقل على الصيانة ووقت التوقف عن العمل، مما يعزز الكفاءة ويخفض التكاليف.

وقت النشر: 9 يونيو 2025